Vertical Hanging Laminar

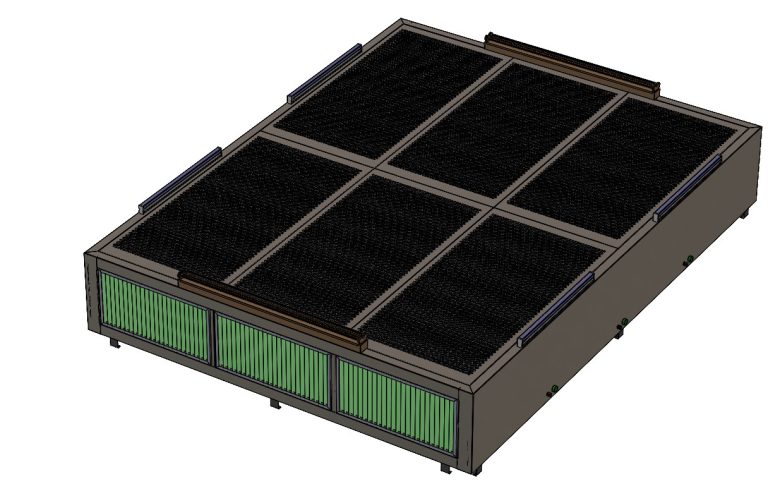

Vertical Hanging Laminar (VHL) unit is a containment equipment module utilizing a zoned unidirectional (laminar) downflow supply of air to positively pressurize and purge the working environment from potential contaminants; thereby providing enhanced aseptic work zones for maintaining process integrity and/or product protection.

THERMADYNE Vertical Hanging laminar (VHL) workstations is must for providing ultra clean work area for semi conductor manufacturing, pharmaceutical filling and capping , electronic & mechanical precision assemblies, analytical test labs etc. manufactured to international

standards, these units incorporate D.O.P tested & point to point scanned Hepa filters .

Key Benefits Of Vertical Hanging Laminar

"Explore the benefits of our Vertical Hanging Laminar Flow

VHL with ISO class 5 (class100)

PLC based control with digital differential pressure gauge, Hepa filter life indicator and alarm

Durable stainless steel construction

Easy to maintain

Energy efficient blowers

Industry-leading customization options

UV stabilized polycarbonate side 1 feet drop

Applications of Vertical Hanging Laminar Flow Units

Achieve contaminant-free air zones with our vertical hanging laminar flow units, ideal for cleanrooms and critical environments.

• Optical Assembly

• Filling Line System ISO Class 5 coverage

• Pharmaceutical Preparation

• Nanotechnology

• Space Industry

• Microelectronic Fabrication and Assembly

• Electronics instrument Assembly

• PCB Manufacturing

• Biotechnology

• Space Industry

Key Specifications

Below are the detailed specifications of our Vertical Hanging Laminar Flow

Standard Sizes

Choose from our range of standard sizes for quick and convenient solutions to fit your needs

Get in Touch for Customized Solutions

Contact us now to find out how we can customize our filters for you.